Regenerative ventilation is an innovative and efficient energy solution that holds immense potential for paint shops. Paint shops have specific requirements when it comes to air circulation, air exchange, and humidity control to ensure optimal working conditions and high-quality paint finishes. Regenerative ventilation systems address these needs while also offering significant energy savings and environmental benefits.

Paint shop operations involve the use of various chemicals, solvents, and paints, which can release harmful fumes and volatile organic compounds (VOCs) into the air. These emissions not only pose health risks to workers but can also impact the quality of the paint finishes if not properly managed. Effective air circulation and ventilation are essential to remove these pollutants, ensuring a safe and healthy working environment for employees.

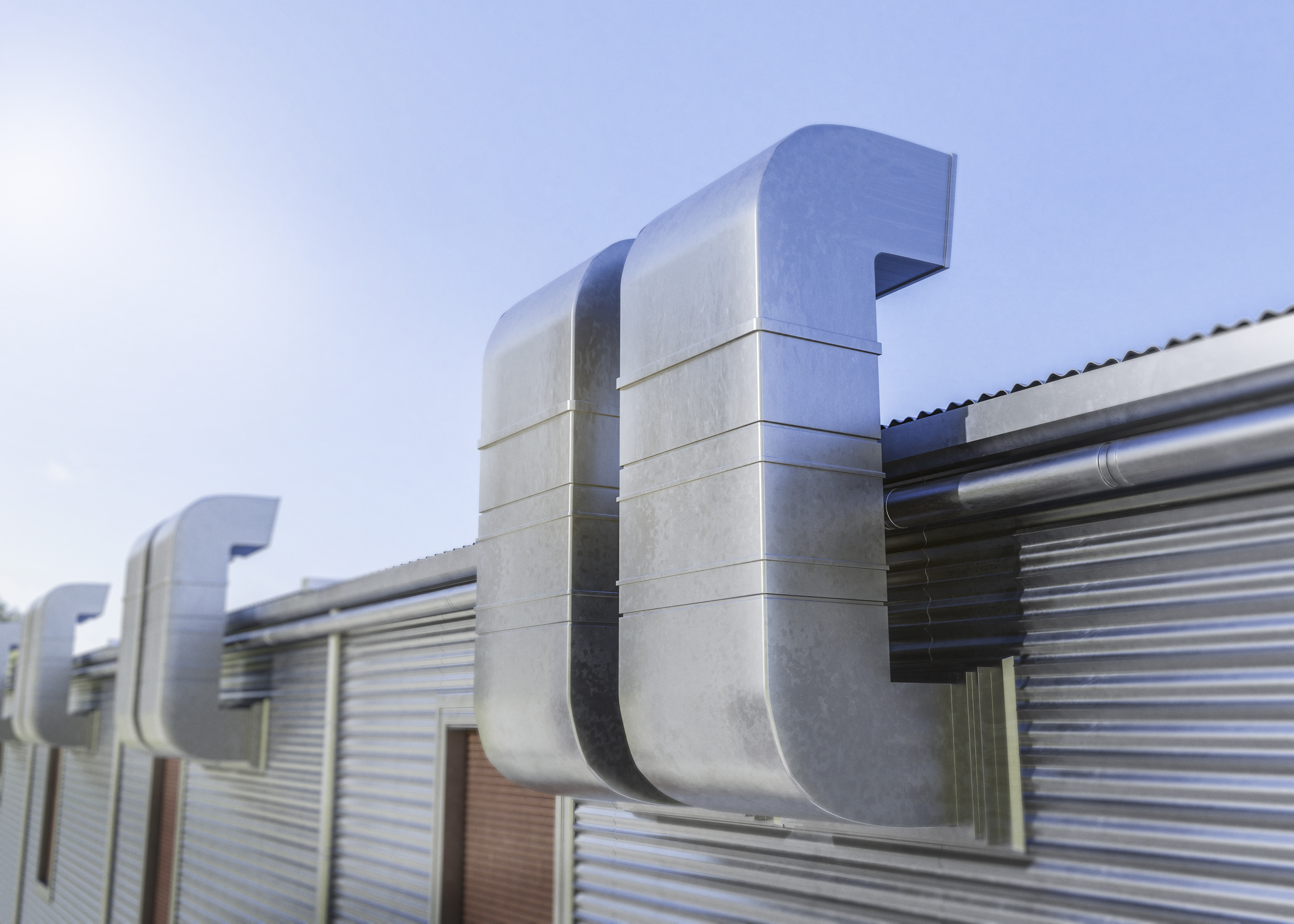

Regenerative ventilation systems are designed to achieve highly efficient air circulation by incorporating heat recovery technology. These systems capture and recover the thermal energy from the outgoing air, transferring it to the incoming fresh air. This process not only helps maintain a comfortable temperature within the paint shop but also reduces the energy required for heating or cooling the air, resulting in significant energy savings.

In addition to energy efficiency, regenerative ventilation systems provide precise control over humidity levels. Paint application requires specific humidity conditions to ensure optimal drying and curing of the paint. Excessive humidity can lead to extended drying times, inconsistent paint finishes, and potential defects. On the other hand, low humidity levels can cause paint to dry too quickly, resulting in poor adhesion and surface quality. Regenerative ventilation systems can incorporate humidity control mechanisms, allowing for precise regulation of humidity levels to meet the requirements of the paint application process.

Furthermore, regenerative ventilation systems contribute to environmental sustainability by reducing energy consumption and greenhouse gas emissions. By recovering and reusing thermal energy, these systems minimize the need for additional heating or cooling, resulting in lower energy demands and reduced carbon footprints. This aligns with the growing focus on sustainability and environmental responsibility in various industries, including paint manufacturing and automotive refinishing.

The implementation of regenerative ventilation systems in paint shops offers several key benefits. Firstly, it ensures a safe and healthy working environment for employees by effectively removing harmful pollutants and maintaining optimal air quality. Improved air circulation helps prevent the buildup of fumes, odors, and airborne contaminants, creating a more comfortable and productive workspace.

Secondly, regenerative ventilation systems provide significant energy savings by recovering and reusing thermal energy. By reducing the demand for additional heating or cooling, these systems lower operational costs and contribute to long-term energy efficiency.

Finally, the precise humidity control offered by regenerative ventilation systems ensures consistent and high-quality paint finishes. Maintaining the appropriate humidity levels throughout the paint application process enhances the overall productivity and efficiency of the paint shop.

In conclusion, regenerative ventilation is an optimal energy solution for paint shops, offering efficient air circulation, precise humidity control, and significant energy savings. By incorporating heat recovery technology, these systems create a safe and healthy working environment, reduce operational costs, and contribute to environmental sustainability. The implementation of regenerative ventilation systems in paint shops showcases the industry's commitment to embracing innovative and sustainable practices while ensuring high-quality paint finishes and employee well-being.

Find Us

International Headquarters

47 East 800 South Ivins

UT 84738

Popular Searches

Be Part of Inair Family

Keep up to date with

exclusive projects

Subscribe

© 2023 – Inair

Privacy Policy© 2023 – Inair

Privacy PolicyLocation